Add:

Dongguan Fortuna Metals CO., Ltd

No. 226, Shida Road, Dalingshan Town, Dongguan 523810, Guangdong, China

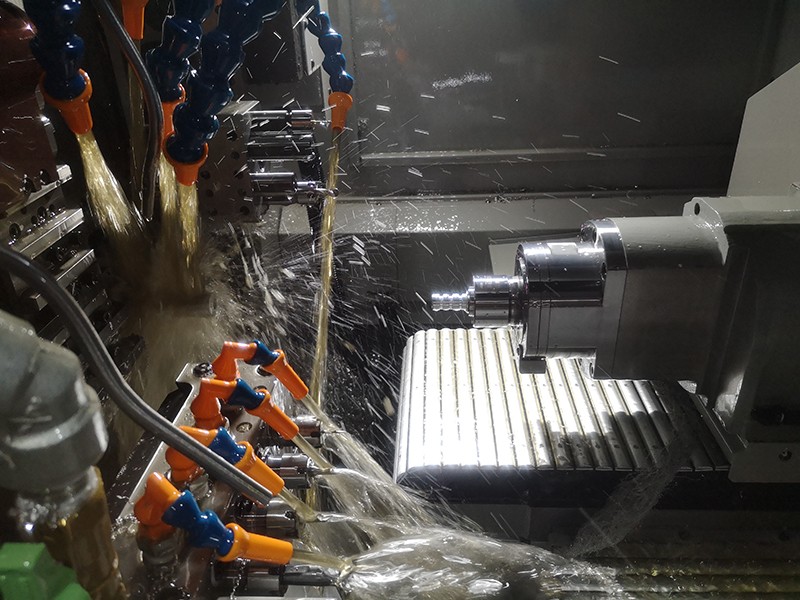

One kind of subtractive manufacturing involves machines that use computer numerical control (CNC) technology to cut workpieces using instructions given by CAD files. CNC machines use tools like turning, milling, and drilling to remove material from workpieces. The machining parameters are specified by g-code and m-code, derived from CAD models.

Metals, plastics, wood, and composites are among the materials that may be efficiently cut with CNC machining. It is a typical way to make components, similar to additive and formative manufacturing procedures like injection molding and 3D printing. Compared to more old-fashioned methods, CNC machining parts offer much more tolerance.

Computer numerical control machining at Fortuna includes several steps in the production process, including planning and programming, setup and machining, checking and quality control, and finishing. This article will examine each step in detail to help readers better understand CNC machining parts and their precision.

A large range of materials may be processed using CNC machining parts machines. The optimal feeds and speeds for machining vary depending on the material. Fortuna uses these high-quality materials in many different contexts:

CNC routers are utilized to cut wood instead of more conventional CNC machines. Aesthetic preferences drive most CNC wood machining projects. Common uses include furniture, ornamental panels, and window frames.

Polyurethane foam, whether closed or open-cell, is an often-used material for CNC machining. A CNC machine can carefully cut foam blocks into packaging for pricey items. The foam used to seal toolboxes is one example of a material that may keep things safe during transportation.

Machines that use computer numerical control work with metal meals the most. Among the various metals CNC machines may cut are nickel superalloys like Inconel and free-machining brass. Injection molds, gears, and shafts are a few metal machining uses. At present, Fortuna can process various Copper (C1100, C10200), Alloy Copper (CUSN38PB2, H62, C3604, C3600, C14500, C17300),Aluminum (AL6262, AL6061), Iron (12L14), Stainless steel (SUS304, SUS303, SUS316L) and other raw materials. Other materials can be purchased according to customer requirements.

Computer numerically controlled machining is an alternative to injection molding that may be used to mass-produce certain plastic components. Most materials are acrylonitrile butadiene styrene (ABS), polycarbonate, or nylon. Plastic machining is a great tool for making injection-molded components, bushings, valve bodies, and other CNC machining parts function as expected before purchasing costly molding equipment.

Composite components are milled using computer numerical control (CNC) equipment. Composites may be constructed from various materials, such as fiberglass, carbon fiber, and aramid. If you use these compounds on your cutting instruments, they may not be as sharp as before. Machining allows for the insertion of fastener holes and general trimming of composite components used in the aviation and marine sectors after molding.

Main Steps For the CNC Machining Part Process

The four fundamental steps of computer numerical control (CNC) machining at Fortuna are technique-independent. Here is an overview of how they function:

Developing a product model in two or three dimensions is integral to this process. Although SolidWorks and AutoCAD are among the most popular choices, a lot of software may do what you need. Depending on the product's needs, it is also feasible to transition from 2D to 3D design.

While some CNC machining parts ideas at Fortuna may be quite straightforward, creating CAD models of more complicated concepts may need the assistance of experts. The CAD model must display all crucial components, including tolerances, construction lines, threads, and more, for the operator to complete the machining process.

The CAD model is foreign to CNC machines. Your computer-aided design (CAD) file must be CNC-compatible for your machine to read. Depending on your needs, this phase at Fortuna might involve using a CAD program, an online service, or something else completely.

This program allows the CNC machine to learn how to set itself up and change file formats to operate. Toolpath, cutting sequence, workpiece, machine speed, and linear and rotational motion are some variables that change during machining.

This step includes choosing the right CNC machine and configuring key tasks before starting the machining process. Workpiece: The right machine is selected based on the available budget. All factors, especially the CNC machining parts play a role in determining the best machine to use for a particular task. The next step is to attach the workpiece to the machine.

The Fortuna operator fastens the essential cutting tools and CNC machining parts before the procedure begins. Due to its automation, this procedure will continue until the computer program says so. Machinists perform a battery of tests before and after milling to ensure quality.

Material is removed from a workpiece in motion when turning using single-point cutting tools. Roughing, finishing, threading, shaping, undercutting, splitting, and grooving are just a few of the many functions that may be accomplished using the wide array of turning tools available. In addition, numerically controlled machines are used in CNC turning. You can choose from various lathes, including turret, engine, and special-purpose models.

Milling is a formative process that uses rotating, multi-point cutting instruments alongside CNC machining parts. End mills, helix mills, and chamfer mills are just a few examples of milling tools used in horizontal or vertical configurations.

Milling machines are capable of running computer numerical control programs (CNCs). They may be set up in either a horizontal or vertical orientation. Most mills have a three-direction spinner, although more complex models have even more spinners. Many different types of mills are available, including basic, universal, and manually driven models.

The material's signature round holes are carved out by drills using revolving drill bits. Chips, or scrap metal, may be easily removed from the treated material due to the drill bit's shape. Drill bits come in a wide variety of styles, and each one serves a specific purpose.

Some examples of drill bits include chucking reamer drills, screw machines, peck drills, and spotting drills. The three main types of drilling bits are spot drills, peck drills, and screw machine drills. Spot drills are used to create shallow or pioneer holes, peck drills to reduce chips in workpieces, and screw machine drills to create holes without a pilot hole. Using chucking reamers, you may enlarge holes that already exist.

Additionally, CNC drilling often uses drill presses and CNC machining parts engineered to carry out the drilling process and fitted with CNC technology. Still, the same outcome can be achieved with turning, milling, or tapping tools.

The many benefits of CNC machining parts have led to its widespread use in manufacturing industrial components. Among the many advantages of this economic activity are the ones listed above.

The precision of computer numerical control machining allows for the manufacture of components that precisely match the specifications laid forth in the design. Because of its high tolerance and precision, many batches of the same product can be made without compromising quality. Because it is an automated process, the machining error rate is decreased.

CNC machined parts have an extremely low turnaround time—just a few days. Consequently, manufacturing becomes more productive. The type of CNC machine and product complexity dictate the speed and efficiency.

Starting CNC machining parts requires a substantial upfront expenditure. However, it has fewer operating expenses. It is cheap to make, produces a lot, and doesn't make mistakes, which only increases its worth. In addition, you can learn most machining processes on your own, and most courses are available online.

With our cutting-edge metal stamping capabilities, we can materialize your ideas. When you work with us, you can expect unmatched dependability and precision. Reach out to Fortuna immediately!

Copyright © 2023 Dongguan Fortuna Metals Co, Ltd. | All Rights Reserved.